Hydrogen Cylinders

Hydrogen cylinders are containers designed to store and transport compressed hydrogen gas. Hydrogen is often stored as a compressed gas because it has a low volumetric energy density in its gaseous form. Storing hydrogen at high pressure allows for a more efficient use of space.

Some key points about hydrogen cylinders:

Material: Hydrogen cylinders are typically made of materials that can withstand high pressures, such as steel or composite materials. Steel cylinders are heavy but durable, while composite cylinders are lighter but may be more expensive.

Pressure: Hydrogen is stored in cylinders at high pressures, usually ranging from 200 to 500 bar for industrial and vehicle applications. Higher pressure allows for more hydrogen to be stored in a given volume.

Safety: Safety is a critical consideration when working with hydrogen. Cylinders must meet certain safety standards, and precautions are taken to avoid leaks, explosions, or other hazards associated with handling compressed gases. EKC takes utmost care in doing so.

Transportation: Hydrogen cylinders are used for transporting hydrogen from production facilities to end-users, such as industrial plants, research facilities, or hydrogen fueling stations. They may be transported by truck or other safer means.

Applications: Hydrogen cylinders find applications in various industries, including energy, manufacturing, and transportation. They are used for processes such as hydrogen fueling for fuel cell vehicles, industrial applications, and laboratory use.

EKC INTERNATIONAL provides Multi Solutions for the Storage of Hydrogen

- High Pressure Seamless Cylinders

- Cylinders Bundle and Racks

- 500 & 1000 Bar Vessels*

- Multi Vessels/Jumbo Tubes Assembly*

- MEGC (Multi Element Gas Container)

- *Manufacturing at CPI -USA

Working Pressure Range:

Working pressure from 200 Bar to 500 Bar.

Manufacturing standards:

ISO 9809-1 (PED & TPED), IS 7285, DOT 3AA.

*Other sizes and manufacturing standards can be offered on request

EKC’s High Pressure Seamless Steel Cylinders are best & safe for Hydrogen and Hydrogen Embrittling gases storage.

Special consideration in Design and stringent quality control processes makes EKC Hydrogen cylinder most reliable and long lasting.

| Working Pressure (Bar) | Diameter (mm) | Water capacity range (Litres) | Approximate Weight (Kg) | Approx.Weight of Hydrogen @ 25° C (Kg) |

| 200 | 229 | 25-80 | 29-78 | 0.36-1.16 |

| 267 | 30-110 | 37-107 | 0.43-1.45 | |

| 325 | 50-165 | 64-165 | 0.72-2.32 | |

| 356 | 55-200 | 68-200 | 0.87-2.90 | |

| 406 | 70-250 | 100-258 | 1.01-3.62 | |

| 250 | 229 | 25-80 | 37-99 | 0.44-1.32 |

| 267 | 30-110 | 48-138 | 0.53-1.76 | |

| 325 | 50-160 | 81-203 | 0.83-1.82 | |

| 356 | 50-190 | 90-248 | 1.06-3.34 | |

| 406 | 70-240 | 126-327 | 1.23-4.22 | |

| 300 | 229 | 20-80 | 46-117 | 0.41-1.54 |

| 267 | 30-100 | 59-156 | 0.62-2.05 | |

| 325 | 40-150 | 86-238 | 0.82-3.08 | |

| 356 | 50-180 | 109-290 | 1.03-3.70 | |

| 406 | 70-240 | 155-392 | 1.44-4.93 | |

| 350 | 229 | 20-75 | 54-137 | 0.47-1.63 |

| 267 | 30-100 | 70-186 | 0.70-2.33 | |

| 325 | 40-150 | 101-284 | 0.93-3.26 | |

| 356 | 50-175 | 129-337 | 1.17-4.08 | |

| 400 | 229 | 20-70 | 63-151 | 0.52-1.82 |

| 267 | 30-100 | 81-218 | 0.65-2.46 | |

| 325 | 40-145 | 117-321 | 0.91-3.63 | |

| 450 | 229 | 20-70 | 72-174 | 0.57-1.85 |

| 267 | 25-90 | 33-228 | 0.71-2.56 | |

| 500 | 229 | 20-65 | 82-186 | 0.62-2.0 |

| 267 | 30-90 | 107-267 | 0.72-2.77 |

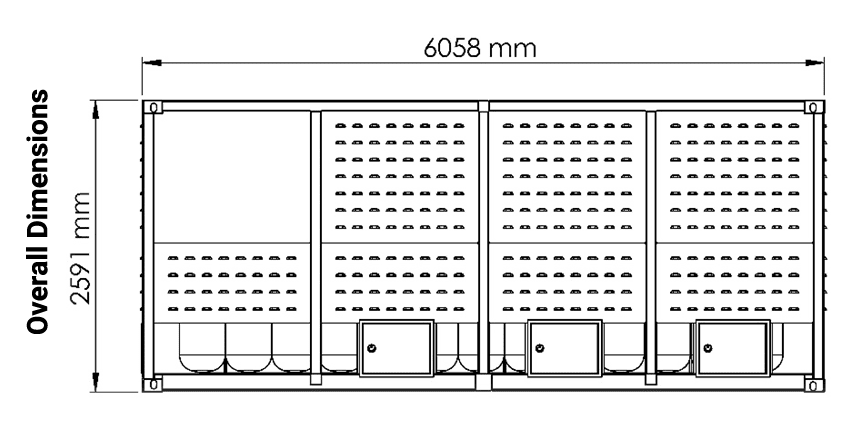

MEGC for Storage & Transportation of Hydrogen

Salient Features

- Distinct design for Hydrogen application.

- Having high quality S.S valves, fittings and gauges.

- IMDG, ADR & CSC Approved MEGCs.

- Frame made of High strength steel.

- System equipped with safeties.

- TPED/PED Approved cylinders.

| 20 Feet Multi Element Gas Container | ||||

| Size of MEGC | Working pressure (Bar) | Total water capacity (Liters) | Total weight of Hydrogen @25°C (Kg) | Gross weight of MEGC (Tons) |

| 20 Feet (STD) | 200 | 17280 | ~250 | ~22 |

| 20 Feet (STD) | 250 | 16320 | ~287 | ~26 |

| 20 Feet (STD) | 300 | 13650 | ~280 | ~29 |