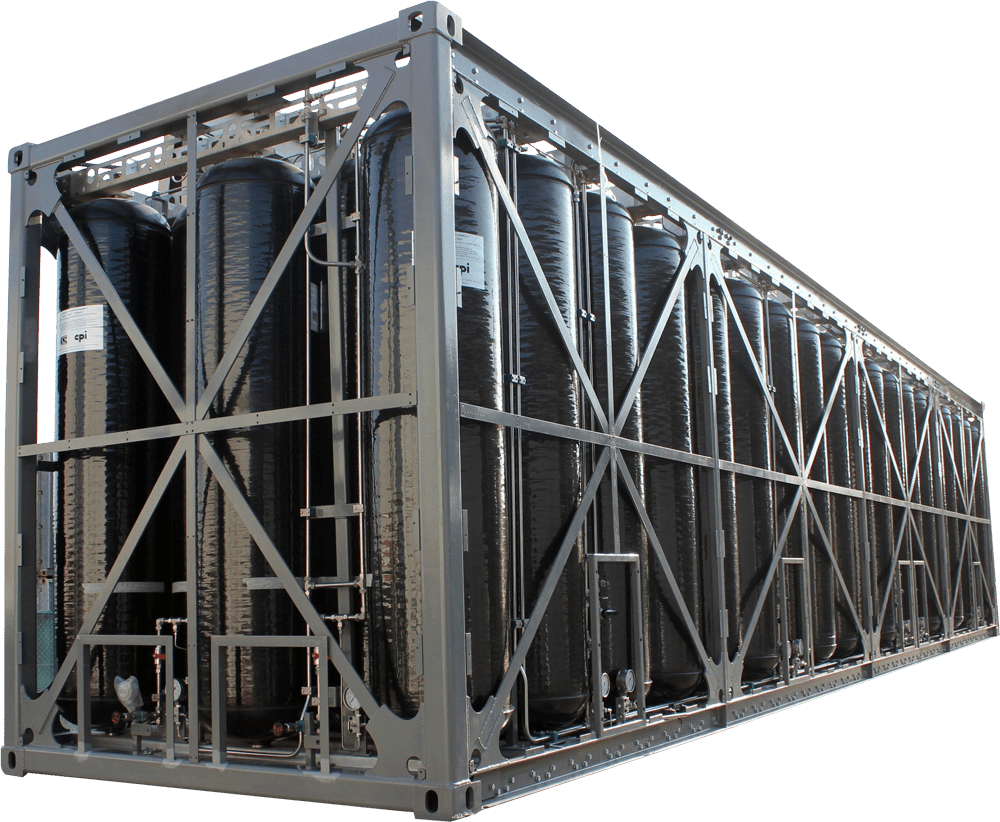

Container for Bulk Transportation of CNG

Model EKC 41013, Type 4, Multiple Element Gas Container (MEGC) manufactured and approved as per ADR standard for CNG application suitable for 40’ Trailer. The container frame is CSC certified as per ISO 668 standard.

TECHNICAL SPECIFICATIONS

| TECHNICAL SPECIFICATIONS | Model-EKC41013 |

| MEGC SPECIFICATIONS | |

| Storage Pressure (Wp) | 250 Bar |

| Total Water Capacity | 41013 Liters |

| Total Gas Capacity** (m ) | 12555 m (approx.) |

| Total Gas Weight (in Kg) | 8789 Kg (approx.) |

| Number of Elements | 93 Nos |

**Note: CNG capacity is based on normal condition at 20 degree Celsius temperature and atmospheric pressure at 1.01 Bar.

MEGC DIMENSIONS

| Length | 12192 mm |

| Width | 2438 mm |

| Height | 2896 mm |

| Empty Weight (approx.) | ~ 18.7 Tons |

| Total weight including gas (approx.) | ~ 27.67 Ton |

CYLINDER SPECIFICATIONS

| Manufacturing standard | ISO 11119-3 |

| Type | Full Carbon Composite, Type 4 |

| Cylinder neck | Double neck |

| Design pressure | 250 bar (3625 PSI) |

| Design service life | 20 years |

Salient Features

- EKC’s special designed Type 4 MEGC has double neck cylinders, placed vertically and interconnected. Top side Necks of cylinders are connected to the pressure line via isolation valves having thermal and pressure safety relief devices and the bottom side necks are connected to the “drain line” as an option.

- EKC’s MEGC has unique design whereby we are providing a drain line facility in our system to facilitate periodical draining of the water & compressor oil residue settled at the bottom of elements in order to keep the elements & system in healthy condition and in order to utilize the maximum gas carrying capacity of the elements and also to avoid carrying dead weight in the trailer.

- All cylinders will be certified for conformity to the relevant manufacturing standard by third party certification agency like Arrowhead, U.K.

- Structural stability, manifold design, testing, inspection and certification for ADR will be carried out and approved by Third party agency (Apragaz Belgium)

- Usage of High-Density Polyethylene (HDPE) Liner of the cylinder imparts highest corrosion resistance and least amount of permeability.

- Filament wound epoxy Carbon fibre composite shell is a high strength material and shows no fatigue during operation.

- Polyurethane protection caps are applied to the domes to

- increase impact and abrasion resistance.

- Our design provides high gas flow rate due to proper selection of tube diameters and gas passages in the manifold. Optimized manifolds and line for best fill and discharge rates.

- Low noise level during filling and discharging based on optimized piping and manifold design

- All joints connected with High Quality SS compression fittings; welding is not used.

- Gas filling/discharging point is provided at the rear end of the MEGC for ease of operation.

- To reduce time for filling/discharge, multiple receptacles can be provided (optional).

- Complete unit construction on standard 40’ ISO 1496-3 container.

- 93 Elements assembled in a 40’ CSC container having 12555 M storage Capacity weighs only 18700 Kgs

EKC MAX – STORE 40FT DESIGN MEGC (TYPE IV)

- EKC MAX-STORE 40FT design 93 cylinders of 441L made of type IV cylinders

- EKC MAX-STORE has unique design with one of the largest capacities with light weight of 18.7 tons.

- Large capacity container effective way of transporting gas in order to achieve a maximum quantity of gas 12,815 m3 gas. Large volume gas transporter pay back on capex on much faster.

- The structure is designed as per ISO ICC container standard ISO 886. The standard dimensions of a high cube container L 12192 x W 2438 x H 2896.